Reducing material and carbon footprints with metallised barrier sealants

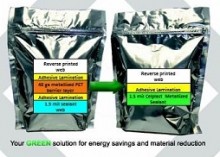

Packaging Films 1-2013 One of the most common flexible packaging formats is the stand-up barrier pouch. This structure typically consists of three layers as shown in figure 1. These structures include a PET/print/adhesive/metallised PET/adhesive/ sealant or PET/print/adhesive/metallised OPP/sealant, with each of these layers playing a functional role in the overall structure. Figure 1: Comparison of 3-ply vs. 2-ply structures for stand- up pouches. The printed PET provides a surface for excellent printability and adds stiffness to the structure. The metallised layer provides an oxygen and moisture barrier in case of metallised PET or moisture barrier in the case of metallised OPP, and also improves stiffness. Metallised films in general provide good aesthetic value and allow for eye-catching graphics, which may be a brand owner requirement in some finished structures. Lastly, the sealant layer provides sealing for the pouch which must also have good COF (coefficient of friction), HSIT (heat-seal initiation temperature), and seal strength, which are critical to downstream processing and performance. Metallised sealants allow converters and brand owners to improve their carbon footprint by reducing material and energy usage when transitioning from a 3-ply structure to a 2-ply structure with- out compromising barrier perform- ance or other key performance cri- teria such as COF and HSIT, which are critical in downstream process- ing (figure 1 and table 1). Based on the […]

Read More...