By applying a flexo coating immediately after the metallizing zone in a vacuum chamber, and then E-beam curing that coating all in one pass, the inherent barrier of that metallized layer is locked in, with a minimal number of coating defects.

Read More...

Flexographic printing/coating method inside of the vacuum metallization chamber and optimizing coating chemistry for enhanced stability in vacuum.

Read More...

An innovative way to improve barrier in flexible films is to lock-in the metallized barrier and protect it from scratches in down-stream processing with a protective top coat.

Read More...

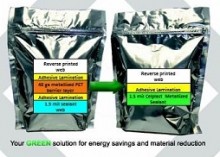

Two trends are driving much of the innovation in laminations using metallized film today. Sustainability has become a key driver for companies in the packaging and converting industry and it is a major area of focus for consumers, retailers, brand owners, converters and legislators. It has become apparent over the last few years that this is not a trend but a core belief and means of reducing costs throughout the packaging industry1.

Another trend is a move to higher barrier packaging. As the market becomes more fragmented with a proliferation of SKU’s, these SKU’s are more likely to spend time in the supply chain before being purchased by the consumer. In addition, a move to healthier, all-natural foods with fewer preservatives means barrier requirements are increasing even for products spending the same amount of time in the supply chain and on store shelves.

Read More...

Presentation by Veronica Ataya TAPPI PLACE May 2012 Download PDF of Presentation Slides: Inline Coating and Metallizing Improve Barrier and Reduce Carbon Footprint

Read More...

In the absence of a consensus among consumers and legislators, major retailers, particularly Wal-Mart in the North American market, are driving the sustainability agenda. Their Packaging Scorecard and recently unveiled Sustainable Products Index provide a roadmap to brand owners and converters as to how they will be graded on the sustainability of their products and packaging.

Read More...

It is clear by now that retailers are the main drivers of the sustainable packaging movement, and they have put their money where their mouths are. Wal-Mart, Tesco and many others have developed comprehensive sustainability programs, including sophisticated measurement tools and hard targets. The second thing that has become clear is that economics drive sustainability, not vice-versa. Sustainability programs have come to encompass sustaining the economics of the packaging as well as sustaining the environment, which means the most successful offerings will improve the bottom line as well.

Read More...

There is decent availability of land in North America for landfills. However, the vast majority of people do not want landfills located near them or their food sources, particularly in high density areas in and around cities where most garbage is produced. Maintaining the infrastructure and logistics around a landfill is becoming increasingly costly for municipalities. These costs are passed on to the consumer via consumer goods tipping fees or higher local taxes. In addition, younger generations are particularly engaged in the idea of more sustainable, environmentally conscious solutions, and identify landfills as a worst-case last resort option only. Many retailers, CPG’s, automotive companies and their suppliers have responded by engaging in activities that either reduce or eliminate their landfill waste. For many companies, their efforts are not solely to satisfy consumer demand. They also believe landfill reduction activities contribute to their long-term financial sustainability by reducing waste disposal costs. They also believe these activities will improve relations with the local municipalities they operate in and enhance their standing within the community.

Read More...