Metallized Polyethylene enters the Circular Economy with offerings of high barrier, recyclable films that compete head to head with barrier properties of traditional packaging structures.

In an effort to develop fully recyclable packaging, the all PE pouch has many features going for it: great seal strength, acceptance in the How2Recycle® Store Drop-Off program in North America, and it is accepted as a mono-material structure by the Recyclass program in Europe. However, the all PE pouch has three major limitations: low stiffness, slow fill speeds and poor barrier.

All of these limitations can be addressed with Celplast’s new DURAMET® line of top-coated metallized PE sealant films. Available in both 38 and 50 micron versions, these films offer good stiffness, good fill speeds via a low HSIT, and excellent barrier performance. Combined with a high stiffness, heat resistant PE print web, converters can now offer fully recyclable all PE pouches that provide high barrier.

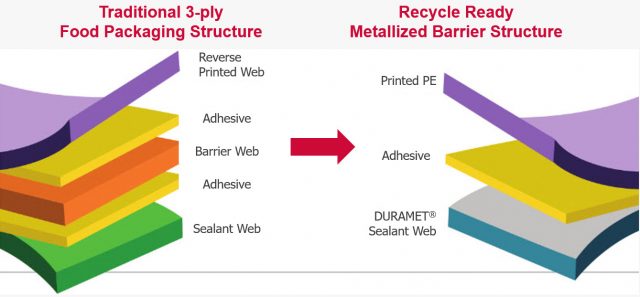

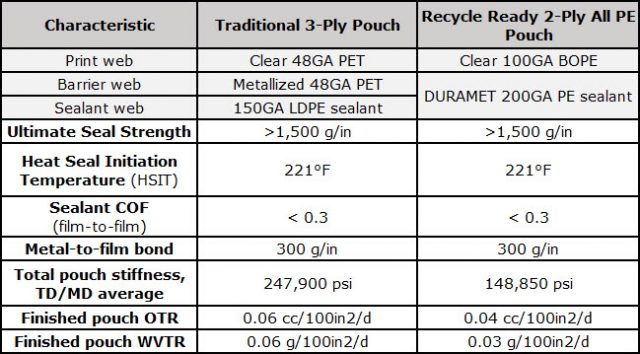

These two-ply all PE pouch structures can replace traditional three-ply barrier pouch structures with similar properties, as shown here:

A High Barrier Film for the Circular Economy

The DURAMET® PE sealant film works because it combines a high stiffness, excellent sealant web with some inherent barrier performance combined with the high barrier Metacoat® in-line metallizing and top-coating technology used at Celplast. This film has been laminated to high stiffness PE and BOPE films, and made into finished pouches. In all cases, the film retains both its high metal bond performance, as well as its barrier properties.

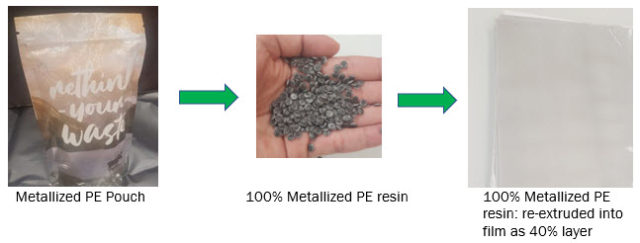

And what happens when a metallized film is re-processed through a recycling stream? A 2016 study by industry consortium REFLEX1, promoted by CEFLEX, showed that a metallized PP stream can be re-processed into molded parts with suitable mechanical properties. We took this a step further, and, working with our partner CharterNEX, actually took our 100% metallized DURAMET® PE film, re-processed it into pellets, and re-extruded it at 100% loading as a 40% layer into a coex film. In this controlled test, the extruded film had a light gray tinge to it, but was gel-free and had good clarity and mechanical performance.

Circular Economy Reality

Through the work being carried out by CEFLEX in Europe, and the Materials Recovery for the Future and Sustainable Packaging Coalition in North America, the commercial sorting and re-processing of pouches containing metallized films is now getting closer to reality2,3. In fact, a metallized PE pouch recently met the RecyClass standards for the EU PE film recycling stream4. Metallized PE pouches are a growing and increasingly necessary part of the circular economy around the world, as brand owners who are committed to the New Plastics Economy continue to develop packaging structures that are 100% recyclable, compostable or reusable by 2025.

2 Cooper, T.A. “Developments in end-of-life technologies for flexible packaging”, AIMCAL R2R & SPE FlexPackCon, Oct., 2019.

3 Mascaro, J., Sr. “Materials Recovery For the Future: How can we capture more value from recycling?”, AIMCAL R2R & SPE FlexPackCon, Oct., 2019.

4 Constantia press release, Oct. 15, 2019. http://www.cflex.com/news/detail/view/ecolam-high-plus-tested-by-recyclass