Store Drop-Off is the only recyclability option for flexible packaging at scale in North America today. The How2Recycle® team has been working on many aspects of testing, including anything added or applied onto a standard, base PE film. The How2Recycle team is also working hard resolving the uncertainties surrounding metallized film and recyclability.

Read More...

How can existing packaging films play a roll in achieving high-barrier recyclable packaging solutions?

Read More...

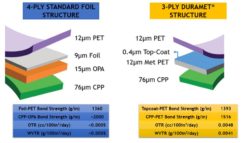

Interest in foil replacement alternatives has surged as antidumping duties ranging from 96% to 162% take effect. Learn about viable and readily available foil alternatives from Celplast.

Read More...

Celplast debuts its DURAMET film and revolutionary new metallizer top-coater at open house event.

Read More...

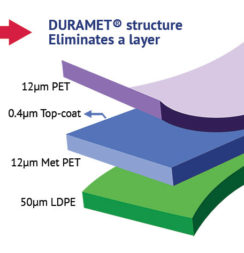

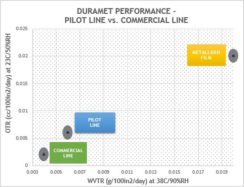

Celplast Metallized Products Limited installed the first of its kind in-line top-coater metallizer in the world earlier this year to produce protected high-barrier materials for the flexible packaging and converting industry. Initial commercial line barrier results of DURAMET® 48 g polyester have surpassed pilot line barrier values with oxygen of 0.033 cc/m2/day. and water vapor barrier of 0.062 g/m2/day.

Read More...

Celplast Metallized Products brings a lower cost, lower carbon footprint alternative to foil to the high barrier flexible packaging market with its revolutionary DURAMET® top-coated metallized PET film.

Read More...

REFLECT-MET is a low-E (0.05 emissivity), corrosion resistant, metallized polyester facer for use in reflective and radiant barrier building insulation, VIPs (vacuum insulation panels), clothing and protective packaging. Web widths available up to 98”.

Read More...

Celplast Metallized Products, Toronto, Ontario, captured the Technical Award for its role as the metallizer of an in-mold label for injection-molded tubes of hair care products from It’s A10

Read More...

AIMCAL Product Competition Award Winners March 2015 Packaging: Nonfood: Marketing Celplast Metallized Products, Toronto, Ontario, captured the Marketing Award at the AIMCAL winter conference. Celplast is recognized for their role as stripe metallizer of high barrier aluminum oxide coated polyester. Other participants in creating the package include converter Prairie State Impressions, Franklin Park, IL, and substrate supplier Camvac Ltd., Thetford, UK. The metallized zippered pouch for Gold Strike Robusto cigars from Swisher International, Inc., Jacksonville, FL combines 48-gauge PET/48-gauge aluminum oxide with stripe metallized PET/2-mil PE. The finished package achieves multiple benefits with high barrier properties and eye-catching graphics. According to Celplast, half of the aluminum oxide-coated PET is metallized. The stripe-metallized film is then laminated to the printed web. High barrier properties of the aluminum oxide allows Prairie State to run a single web instead of two webs reducing material costs by more than 25 percent. The lamination also permits higher printing and pouching speeds for increased efficiency. The resealability feature with the zipper and product visibility through stripe metallizng creates value and great shelf appeal for the consumer. “A 25 percent cost reduction is substantial,” stated one judge. The judging panel also liked the resealability of the package.

Read More...

New High-Barrier Materials & Product lines Coming in the Future Celplast will bring to market a proprietary manufacturing process thanks to an investment of up to $2.075 million by the Federal Economic Development Agency for Southern Ontario (FedDev Ontario). The funding will be used to purchase a new metallizer machine and have it customized to include proprietary and unique in-vacuum coating technology. This technology will allow Celplast to create a lower-cost film with better barrier properties for immediate applications in the food packaging and industrial markets. FedDev Press Release Link

Read More...

March 2014 Packaging: Food & Beverage: Marketing Celplast Metallized Products The AIMCAL Marketing Award in the Food Packaging Category went to Celplast Metallized Products, Toronto, Ontario, Canada, for metallized, light-blocking low-density polyethylene (LDPE) bags for four varieties of potato from EarthFresh Farms, another Toronto-based firm. Celplast metallizes 1.25- or 1.75-mil LDPE from Tempo Plastics Ltd., Innisfil, Ontario, and returns it to Tempo for conversion into wicketed bags. Stripe metallizing provides product visibility while blocking most of the light that would reach the potatoes in a standard poly bag. Eliminating light exposure prevents the potatoes from turning green (and bitter) and more than triples shelf life to 21 days. Bags are punched with two parallel rows of ventilation holes and printed with bilingual product and brand information as well as alternate serving suggestions. Color coding identifies Roasting (gold), Boiling (green), Baking (red) and Mashing (blue) potatoes. Judges Comments Judges noted potato bags tend to be heavier gauge film or woven. “We really haven’t seen anything like this for fresh potatoes,” said one member of the panel. “It opens the door to greater use of metallized packaging in the produce department,” predicted another.

Read More...

Celplast Metallized Products recently co-presented a paper with Larry Jopko of Dow at the TAPPI Barrier Symposium at ICE in Orlando, FL, entitled “How good is your barrier packaging in the real world?” This paper focused on barrier properties and lamination bond strengths of 2 ply and 3 ply metallized film structures, both before and after gelbo flexing. Two different high barrier metallized films were examined: Barrier Sealant metallized PE and Metacoated PET. Three different adhesive systems were evaluated: solvent based, solventless and water based. The Barrier Sealant in a 2-ply structure, laminated to clear PET, gave the best performance in terms of retaining barrier properties after Gelbo flexing. Celplast Metallized Products is a leading supplier of high barrier films to the North American converting industry, including SUPERMET™ and ULTRAMET™ for high metal adhesion, and FOILMET™ for high barrier. Celplast is also the exclusive distributor to North America of the CERAMIS® SiOx-coated and Camclear® AlOx-coated families of clear barrier films. Celplast has recently introduced a family of top-coated metallized films, with a top-coating designed to protect the metal layer from moisture and hot, humid environments. This includes REFLECT-MET™ for reflective insulation and radiant barrier applications, as well as DURA-MET™ for extended shelf life food packaging. Celplast also offers testing for OTR, WVTR, metal adhesion, emissivity, scuff resistance, corrosion resistance and […]

Read More...

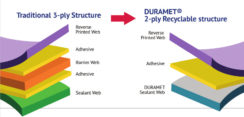

Packaging Films 1-2013 One of the most common flexible packaging formats is the stand-up barrier pouch. This structure typically consists of three layers as shown in figure 1. These structures include a PET/print/adhesive/metallised PET/adhesive/ sealant or PET/print/adhesive/metallised OPP/sealant, with each of these layers playing a functional role in the overall structure. Figure 1: Comparison of 3-ply vs. 2-ply structures for stand- up pouches. The printed PET provides a surface for excellent printability and adds stiffness to the structure. The metallised layer provides an oxygen and moisture barrier in case of metallised PET or moisture barrier in the case of metallised OPP, and also improves stiffness. Metallised films in general provide good aesthetic value and allow for eye-catching graphics, which may be a brand owner requirement in some finished structures. Lastly, the sealant layer provides sealing for the pouch which must also have good COF (coefficient of friction), HSIT (heat-seal initiation temperature), and seal strength, which are critical to downstream processing and performance. Metallised sealants allow converters and brand owners to improve their carbon footprint by reducing material and energy usage when transitioning from a 3-ply structure to a 2-ply structure with- out compromising barrier perform- ance or other key performance cri- teria such as COF and HSIT, which are critical in downstream process- ing (figure 1 and table 1). Based on the […]

Read More...

Cel-Met and O2 Barrier metallized sealants from Celplast permit down-gauging of approximately 25% without compromising the barrier properties or performance of the barrier laminate. The Cel-Met sealant replaces metallized oriented polypropylene to reduce a three-ply structure to two plies while providing an oxygen transmission rate (OTR) of 4.0 cubic centimeters per 100 square inches per day and a water vapor transmission rate (WVTR) of 0.08 grams per 100 square inches per day. The O2 Barrier sealant replaces metallized polyethylene terephthalate to convert a three-ply structure to a two-ply and provides even higher barrier properties: 0.04 cubic centimeters per 100 square inches per day OTR and 0.05 grams per 100 square inches per day WVTR. Eliminating the need for a second pass in the lamination process also conserves adhesive and reduces energy requirements 31% for solvent-based structures and 11% for solvent-less. Carbon dioxide emissions also drop: 34% for solvent-based laminating and 30% for solvent-less. Applications include stand-up and peg-display pouches. Judges Comments The judges noted the metallized sealants reduce steps in the process and achieve a significant source reduction. “It’s a new way of looking at structures and definitely a step in the right direction,” concluded one member of the panel. A detailed article on these Barrier Sealants is available on Converting Quarterly Magazine 2011 Quarter 2 p 56.

Read More...

Celplast, a leading player in the development and manufacturing of high barrier film solutions for converters, recently announced the appointment of Grupo Navegador as their exclusive representative in Mexico. To mention a few of the various film products that Celplast produces, Grupo Navegador will be responsible for sales and promotion of the improved metallized SUPERMET™ product line, the high barrier FOILMET™, the clear barrier films CERAMIS™ (SiOx-coated) and CAMCLEAR™ (AlOx-coated). Grupo Navegador will also be responsible for the introduction in Mexico of Celplast’s new product lines REFLECT-MET™ for reflective insulation and DURAMET™ for flexible packaging products that require an extended shelf life. “Celplast’s wide range of barrier films open new doors for the converter,” says Sergio González de Cosío, Commercial Director for Specialty films within Grupo Navegador. “These films from Celplast will provide high value to projects that can take advantage of the films’ extraordinary properties. We are very pleased to partner with Celplast in promoting these product lines in Mexico.” Celplast’s barrier films are available in a wide variety of substrates such as polyester, BOPP, nylon and PE; metallized or coated with SiOx; and in a wide range of thicknesses. “We are excited to be able to offer the Mexican converters our outstanding products. The demand for our high-end specialty films has grown tremendously over the last few years, which […]

Read More...

Celplast Metallized Products / VAST Films’ new Metacoat™ allows coating, metallizing in a single pass, dramatically cuts costs, builds better barrier properties, protects surface from micro scratches. Mark Spaulding — Converting Magazine The Association of Industrial Metallizers, Coaters and Laminators (AIMCAL) presented its Technology of the Year Award toCelplast Metallized Products Ltd. / VAST Films Ltd., Toronto, Ontario, Canada, for its Metacoat™ roll-coating technology on Sunday, March 21, 2010, at a banquet during its annual Management Meeting, March 21-24 at the Hilton La Jolla Torrey Pines in La Jolla, California. The patent-pending Metacoat technology allows coating and metallizing to occur in the same pass at standard metallizing speeds. A gravure coating station applies an acrylate and/or methacrylate liquid to the film surface and cures it immediately via electron beam exposure. Coating can occur before or after metallizing. Eliminating separate metallizing and coating passes dramatically improves economics. It also can increase a metallized film’s barrier properties because top-coating immediately after metallizing protects the metallized surface from micro scratches and defects caused by roller contact and downstream processing. Immediate applications include packaging, insulation, reflective displays and flexible electronics. In time, additional applications may include food packaging, metallized transfer film, hot-foil stamping film, solar collectors, photovoltaic cells, optical coatings and scratch-resistant coatings for decorative panels. Celplast currently produces 39-inch-wide coated/metallized material on a […]

Read More...

Date: Dec. 2, 2008 Re: Employee Buy-in Chuck Larsen, CEO; Bill Hellings, President; Dante Ferrari, COO Celplast Metallized Products Limited (CMP) announces the sale of a 20% stake in CMP to an employee group led by Dante Ferrari. Plans are in place for them to acquire a majority position over 7 – 10 years. This action brings in a group of talented young people to the ownership of the company, and ensures a gradual and smooth management transition. Celplast Limited, CMP’s parent company, will maintain a long term interest in the business. CMP will continue its commitment to offer the North American converting industry’s best customer service. With a secure future and a continued focus on employee education and customer-centered innovation, CMP is ready to grow with its customers over the long term. Should any of you wish more information, please contact Chuck Larsen (x- 231), Bill Hellings (x-222) or Dante Ferrari (x-256) at 416-293-4330. Sincerely yours, Chuck Larsen Bill Hellings Dante Ferrari Celplast Limited Celplast Limited EBG Limited From: Celplast Limited, Chuck Larsen and Bill Hellings EBG Limited, Dante Ferrari

Read More...

In the Industrial Category, Celplast received the Technical Award for its REFLECT-MET™ top-coated metallized PET, which is used in AstroShield material, a low emissivity product sold by Innovative Energy Inc., Lowell, Indiana, for applications requiring reflective insulation or a radiant barrier. Converted by Pregis Innovative Packaging Inc., Plymouth, Indiana, and used primarily in building construction and remodeling, the AstroShield options include REFLECT-MET™/bubble/bubble/Reflect-Met, Reflect-Met/white bubble or Reflect-Met/white bubble/white bubble. The coated metallized layer helps the lamination meet water vapor transmission, strength, thermal and fire performance requirements, while providing a brightness similar to foil. In fact, the REFLECT-MET™ layer meets reflective insulation standards for moisture corrosion resistance (ASTM D3310), vapor retarding (ASTM E-96), aged vapor retarding (ASTM C1258) and emissivity less than or equal to 0.05 (ASTM C1371). The coated metallized polyester also is significantly more machinable than thin-gauge foil because its resists the tear-outs and creasing that typically generate scrap rates ranging from 4% to 8% for foil laminations. Perhaps, most importantly, the REFLECT-MET™ metallized polyester meets pending changes to the ASTM E-84 flame test, which will render laminations using an unprotected foil layer unacceptable. Finally, the fiber-free lamination comes in easy-to-handle rolls, requires no custom installation tools, and eliminates the need for any special personal protection equipment. Although insulation is a big market for metallized material, the judges concluded, “We […]

Read More...