It’s 2019 and the plastic choke is well and truly on. One wonders about how much longer before the ocean “taps out” and pictures, like the one below, of a garbage patch off the coast of Hawaii make for grim reading.

Challenges

Plastics in our environment is a growing challenge, especially since plastic production is expected to double over the next two decades. A major portion of this amount is and will continue to be used in packaging, which currently represents 26% of the total volume of plastics used. Only 14% of plastic packaging is collected for recycling and after factoring in additional value losses in sorting and reprocessing, only 5% of material value is retained for subsequent use. Creating a high-performance recyclable or compostable package is a challenge as the functional requirements of oxygen and moisture barrier are extremely difficult and expensive to meet with existing substrates and technologies.

On the other hand, brand owners are key stakeholders in the battle to fight food waste, another great challenge of our time. Plastic packaging is essential to delivering high-quality products to consumers without these products spoiling in the supply chain, whether in traditional or E-commerce retail channels. Therefore, rather than committing to eliminating plastic packaging, which would greatly increase the amount of food waste, many leading brands, retailers and packaging companies have committed to using 100% reusable, recyclable or compostable packaging by 2025. Staying true to our vision of “leading the market with the quickest response to changing customer needs”, Celplast is delivering solutions to fulfill these commitments.

Top-Coating for Barrier

At the heart of these innovations is Celplast’s licensed Metacoat™ technology on recyclable film substrates like polyethylene (HDPE, LDPE) and polypropylene (CPP & OPP) and compostable film substrates like polylactic acid (PLA). Metacoat involves the deposition and e-beam curing of a polymer top-coat on the metal layer, under vacuum, thereby protecting the metal from any scratches or pinholes. This, in turn, retains the inherent metal barrier and allows for a Barrier Improvement Factor (BIF) of 6 to 10x over traditional metallizing. The Metacoat technology has resulted in the development of our high barrier DURAMET® family of films as outlined in the chart below:

Compostable Solutions

Compostable packaging solutions are mostly offered for single-use low to mid barrier requirements as metallized PLA can only offer a certain barrier against moisture and oxygen. With the development of a top-coated metallized PLA solution, the compostable packaging market will be able to enter high barrier packaging formats, and this will allow consumer goods companies to eliminate layers in packaging structures, thus lowering costs and environmental impact.

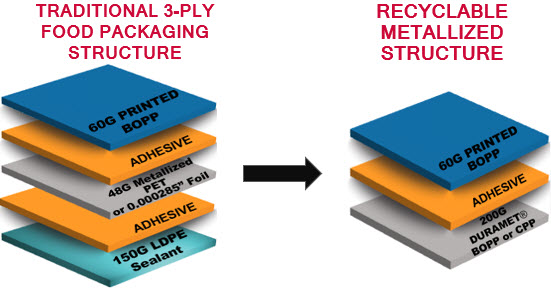

Recyclable Film Opportunities – Layer Elimination

On the other hand, the existing infrastructure for flexible packaging recycling can only accept multi-ply structures made of the same film such as PE or PP. However, structures made of the same layers do not offer high barrier, which is why layers such as metallized PET need to be added. A potential solution to this problem is a high stiffness, top-coated metallized PE or PP film as the barrier performance will be improved considerably. Therefore, multi-ply structures of the same films will be able to exist and pass through existing recycling streams. At the same time, this will create opportunities for layer elimination, lowering costs and reducing environmental impact.

Here are some schematics of layer elimination opportunities with recyclable metallized structures:

More to Come

Consumer-driven change and innovation don’t become reality through magic; it takes sweat, determination, and hard work and there is plenty of the latter left to do. Metal adhesion on PLA, PE & PP films and compatibility of existing recycling infrastructure with metallized films are a few questions that Celplast has been focusing its efforts on. We are confident in presenting these answers soon.

Stay tuned!

-Ameer

ahamza@celplast.com

Ameer Hamza

Product/Process Development Engineer

Celplast Metallized Products

Providing the industry’s best customer service