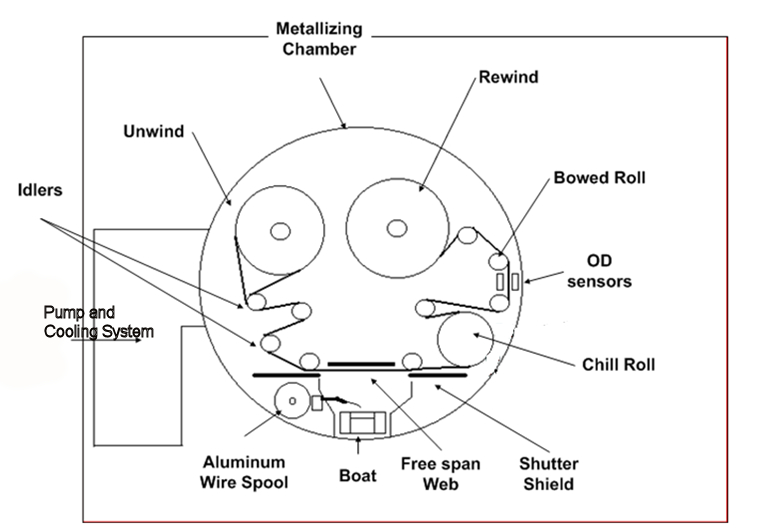

Vacuum metallizing takes place in a cylindrical chamber in which the air is pumped out via diffusion pumps to achieve an atmosphere much like that of the moon. Unwind and rewind stations are positioned in the chamber allowing the film to pass from unwind to rewind over the active boat bed area of the chamber, where aluminum is melted at 1500 degrees celsius and forms a vapor cloud above the boat bed. As the substrate passes over this active area, a thin layer of aluminum is deposited onto the film, thus creating a barrier layer. The aluminum coating is measured in angstroms and typically represents less than 0.1 percent of the base film and therefore does not affect the yield or mechanical properties of the base film.