It’s a challenge to find or create a metal adhesion test that can be performed in a non-converting facility and still be meaningful enough to be representative of the actual converting processes. A metal adhesion value represents the force it takes to separate the layers of a laminated structure and is important to understanding whether the metallized substrate is performing in the structure as it should.

First in metal adhesion testing, there was the Scotch 610 tape test. This is the method where 3M 610 tape is applied to the metallized surface of the film and is then pulled away at a 180 degree angle at a controlled rate. The amount of metal that transfers to the tape determines the integrity of the metal adhesion to the film. From my experience unless the metal adhesion is already visibly poor, the metal does not decal from the film, so this is in essence a go or no-go test.

Another more detailed metal adhesion test used by Celplast (MA-1) is a modified version of the method TP-105-92 published by the Association for Metallizers, Coaters and Laminators (AIMCAL). It consists of a laminated structure (see diagram below) that better represents the converting process. In this method, the metallized film is heat sealed to an EAA/Paper/Foil laminate before tensile testing is conducted.

Specimens of 1” wide are mounted in a tensile tester and T-peeled at 90 degrees with the metallized film in the stationary jaw of the peel tester and the EAA film in the moving jaw of the peel tester. Peel tests are conducted 45 minutes to 180 minutes after the heat sealing.

Using our MA-1 test method, Celplast achieves metal adhesion bonds of 300 g/in for CEL-MET standard metallized polyester, 600 g/in for SUPERMET™ and 1000 g/in for ULTRAMET™. The numerical data provides much needed information in validating the metal adhesion, but there is still a need for more depth to the test to achieve more meaningful results reflective of the converting process.

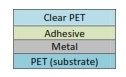

To get still a step closer to replicating what happens in the converting process, the Celplast test method MA-2 was developed. In this method a solvent-based adhesive with 2.5 pounds per ream coat weight is applied to the metal side. Clear polyester film is laminated to the metallized polyester and the structure is cured for 48 to 72 hours at 35 degrees Celsius.

It is important to be able to determine where de-lamination is occurring and with this method, different modes of failure can be identified as shown in the diagram below.

With the MA-2 test ULTRAMET metal adhesion value is 500 g/in, exhibiting polyester failure or substrate failure (PET film tear), this indicates the bond strength of the metal to the film is higher than the strength of the polyester itself. By utilizing the MA-2 test method we have been capable of developing better films to suit the needs of the constantly changing converting industry.

The next challenge will be developing a metal adhesion test for the lab for solvent-less adhesive applications, which is proving to be a very difficult task due to the high viscosity of the solvent-less adhesives.

-Naomi

Naomi Panagapka

Customer Solutions

Celplast Metallized Products

Providing the industry’s best customer service