We’ve all had it happen. We find a roll in inventory, perfect for that rush job, only to find that there is no identification on the roll. How to determine the functional side? Here are some quick tips to get you out of that jam and producing product in confidence. First a quick how to: Ensure the film surface is clean and clear of any contaminates. It is recommended to remove at least one full wrap from the outside of the roll before taking your test sample. Fold the sample so as to have both sides of the film upper-most Draw the dyne pen across the web so to test both sides of the film Evaluate the results Separate sets of pens should be kept for different substrate types Dyne solution pens will quickly and effectively identify the treated surface of many film types. Below show results with dyne solution applied to a treated and non-treated surface of polyester. Polyester: The non-treated side of polyester has a natural dyne level of 44 so you will need to use a high dyne treat pen (58 dyne solution pen is recommended) to determine the treated side. The dyne solution will bead-up immediately on the untreated PET side, while it will wet-out (remain flat) on the treated surface. Polypropylene and polyethylene films: Polypropylene, with […]

Read More...

Dante Ferrari of Celplast Metallized Products will be presenting at the AIMCAL Fall Technical Conference (Oct. 27 – 30 in Charleston, SC). Flexible packaging barrier properties and how it translates to real world use will be discussed. For high barrier flexible packaging, understanding how barrier properties are impacted by handling through pouch-forming, the supply chain and in the consumer’s hands is critical. You may have excellent barrier properties in a laminated rollstock. But what happens to the package in the real world? We studied barriers of 3 different types of metalized films in 2 ply and 3 ply laminate structures, both before and after gelbo-flexing. Three different adhesive systems (solvent-based, solvent-less and water-based) were evaluated, and bond strengths of each finished laminate were also measured. Come join the conversation and discover the truth about barrier properties and how you can improve your packaging!

Read More...

Metal adhesion has long been a challenge in the converter packaging world. The ubiquitous stand-up pouch (Reverse printed PET/Metallized PET/Sealant) and other standard laminated packages, always had intermittent, unidentifiable de-lamination issues, which would crop up from time to time with corona treated polyester and then disappear with no explanation. It was found however that this nuisance issue could be corrected with metallizing chemically treated polyester film. But nothing ever stays the same. Along came hazelnut-flavored coffees, eucalyptus-infused pet treats, large format side-gusseted stand-up pouches and other formats, and increasing usage of solventless adhesives. Delamination issues re-surfaced once again. Polyester laminated to polyester introduces two stiff films which in and of itself, is its’ own challenge. Now, strong flavors,new, larger package formats, and stiffer adhesives have been introduced to the mix adding to the daunting task of achieving high bond strength and subsequent barrier requirements. Our customer needed to achieve better bond strengths that their customer, the brand owner, demanded. In response to this challenge, SUPERMET™, a metallized polyester that provides 600 g/in of metal adhesion to polyester was introduced. The adhesion strength is accomplished through a proprietary metallizing process; but more importantly SUPERMET™ proves to be a viable solution for many structures including the above cited examples. SUPERMET™ was quickly followed by SUPERMET™ HB, a metallized polyester with the same 600 g/in […]

Read More...

It’s a challenge to find or create a metal adhesion test that can be performed in a non-converting facility and still be meaningful enough to be representative of the actual converting processes. A metal adhesion value represents the force it takes to separate the layers of a laminated structure and is important to understanding whether the metallized substrate is performing in the structure as it should. First in metal adhesion testing, there was the Scotch 610 tape test. This is the method where 3M 610 tape is applied to the metallized surface of the film and is then pulled away at a 180 degree angle at a controlled rate. The amount of metal that transfers to the tape determines the integrity of the metal adhesion to the film. From my experience unless the metal adhesion is already visibly poor, the metal does not decal from the film, so this is in essence a go or no-go test. Another more detailed metal adhesion test used by Celplast (MA-1) is a modified version of the method TP-105-92 published by the Association for Metallizers, Coaters and Laminators (AIMCAL). It consists of a laminated structure (see diagram below) that better represents the converting process. In this method, the metallized film is heat sealed to an EAA/Paper/Foil laminate before tensile testing is conducted. Specimens of 1” […]

Read More...

Celplast Metallized Products recently co-presented a paper with Larry Jopko of Dow at the TAPPI Barrier Symposium at ICE in Orlando, FL, entitled “How good is your barrier packaging in the real world?” This paper focused on barrier properties and lamination bond strengths of 2 ply and 3 ply metallized film structures, both before and after gelbo flexing. Two different high barrier metallized films were examined: Barrier Sealant metallized PE and Metacoated PET. Three different adhesive systems were evaluated: solvent based, solventless and water based. The Barrier Sealant in a 2-ply structure, laminated to clear PET, gave the best performance in terms of retaining barrier properties after Gelbo flexing. Celplast Metallized Products is a leading supplier of high barrier films to the North American converting industry, including SUPERMET™ and ULTRAMET™ for high metal adhesion, and FOILMET™ for high barrier. Celplast is also the exclusive distributor to North America of the CERAMIS® SiOx-coated and Camclear® AlOx-coated families of clear barrier films. Celplast has recently introduced a family of top-coated metallized films, with a top-coating designed to protect the metal layer from moisture and hot, humid environments. This includes REFLECT-MET™ for reflective insulation and radiant barrier applications, as well as DURA-MET™ for extended shelf life food packaging. Celplast also offers testing for OTR, WVTR, metal adhesion, emissivity, scuff resistance, corrosion resistance and […]

Read More...

Leadership Development SIG at Celplast Metalized Products Our members were fascinated to learn that the Celplast organization, with roughly 60 employees, has roughly 60 leaders! Yes that’s a 1 for 1 ratio and I must say a few members had raised eyebrows when Marc Jolicoeur, Plant Manager, shared this statistic with us. Celplast has been on a leadership development journey for the past 18 months and has been experiencing incredible results due to their investment in people and leadership. I bet you want to ask “What’s unique about their approach”? Well to be honest, there are a number of unique elements that are coming together to create the momentum in this company. Currently the Celplast program focuses on five key elements. Forward Thinking Senior Management The FISH Philosophy 1/4ly memorable moments Situational leadership Generous recognition and rewards The first element, forward thinking management, is an element that was not specifically mentioned, yet I believe is the most important of all elements. During a trip to the east coast a couple of years ago, Marc experienced the FISH philosophy first hand and recognized that this was a leadership approach that could make a significant impact in his company. Upon his return he approached the management team with the news of what he had uncovered and the process was underway. Clearly without […]

Read More...

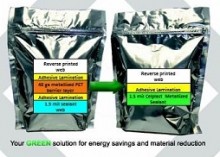

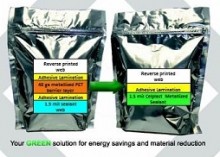

Packaging Films 1-2013 One of the most common flexible packaging formats is the stand-up barrier pouch. This structure typically consists of three layers as shown in figure 1. These structures include a PET/print/adhesive/metallised PET/adhesive/ sealant or PET/print/adhesive/metallised OPP/sealant, with each of these layers playing a functional role in the overall structure. Figure 1: Comparison of 3-ply vs. 2-ply structures for stand- up pouches. The printed PET provides a surface for excellent printability and adds stiffness to the structure. The metallised layer provides an oxygen and moisture barrier in case of metallised PET or moisture barrier in the case of metallised OPP, and also improves stiffness. Metallised films in general provide good aesthetic value and allow for eye-catching graphics, which may be a brand owner requirement in some finished structures. Lastly, the sealant layer provides sealing for the pouch which must also have good COF (coefficient of friction), HSIT (heat-seal initiation temperature), and seal strength, which are critical to downstream processing and performance. Metallised sealants allow converters and brand owners to improve their carbon footprint by reducing material and energy usage when transitioning from a 3-ply structure to a 2-ply structure with- out compromising barrier perform- ance or other key performance cri- teria such as COF and HSIT, which are critical in downstream process- ing (figure 1 and table 1). Based on the […]

Read More...

Presentation by Veronica Ataya TAPPI PLACE May 2012 Download PDF of Presentation Slides: Inline Coating and Metallizing Improve Barrier and Reduce Carbon Footprint

Read More...

November 4th, 2011 – To give back to our local community, Celplast Metallized Products Limited and Underwriter’s Laboratories joined forces to support Habitat for Humanity Toronto (HFHT). HFHT’s mission is to mobilize volunteers and community partners in building affordable housing and promoting homeownership as a means to breaking the cycle of poverty. On November 4th, 2011, 6 volunteers from Celplast and 7 from Underwriter’s Laboratories spent the day getting their hands dirty, bringing the homes one step closer to move-in ready. The two companies’ monetary donation will go towards the purchase of construction materials and help enable future build sites. Once completed, the site at 4572 Kingston Rd. in Toronto will provide residence for 29 families. Work on the site began in September 2010 and is expected to finish by year end 2011. Celplast volunteers pictured from right to left include Krish Tharmal, George Dong, Weijia Zhang, Veronica Ataya, Dante Ferrari and Sid Fernandes. HFHT is part of a global organization which averages completion of a single-family house every 10 minutes. Since its founding in 1976, Habitat for Humanity has helped build or repair over 400,000 houses and served over 2 million people around the world. For more information please visit http://www.habitat.org or your local chapter website.

Read More...

Celplast Metallized Products is proud to announce Veronica Ataya has recently joined the business as Product Development Engineer. Veronica has a Masters degree from the University of Toronto in Chemical Engineering, and completed her Bachelor of Chemical Engineering from Simon Bolivar University in Caracas, Venezuela. She comes to Celplast with valuable sales & marketing experience as a Sales Supervisor with Merkat Imports in Acarigua, Venezuela. Veronica has taken a leadership role in product & process development, and is managing Celplast’s ever-expanding R&D lab. She will be presenting her findings on top-coated metallized film barrier properties at the AIMCAL Fall Technical Conference in Reno, NV, October 23 – 26, 2011. Celplast Metallized Products is a leading supplier of high barrier films to the North American converting industry. In addition to its metallized film solutions, including SUPERMET™ for high metal adhesion and FOILMET™ for high barrier, Celplast also is the exclusive distributor to North America of the CERAMIS® SiOx-coated and Camclear® AlOx-coated families of clear barrier films. Celplast has also recently introduced a family of top-coated metallized films, with a top-coating designed to protect the metal layer from moisture and hot, humid environments. This includes REFLECT-MET™ for reflective insulation and radiant barrier applications, as well as DURAMET™ for extended shelf life food packaging. Celplast also offers testing for OTR, WVTR, metal adhesion, […]

Read More...