Protect your Barrier

However good your barrier layer is, the reality is that the tiniest defect or scratch will have a drastic effect on it’s barrier properties. An innovative way to improve barrier in flexible films is to lock-in the metallized barrier and protect it from scratches in down-stream processing with a protective top coat.

Two Step Vs. In-Line

Taking this a step further, we suspected that pin-holing and scratch defects were being introduced in the traditional two-step top-coat process, and that we could improve upon it by creating a single-step in-line process to top-coat directly in the metallizing chamber. We tested our in-line process and found that indeed, barrier properties improved significantly over the two-step top-coat process. Using what we learned, we have since created DURAMET: an in-line top-coated and metallized high-barrier film. DURAMET films provide a barrier improvement of up to 10-times that of just metallized films.

The Results

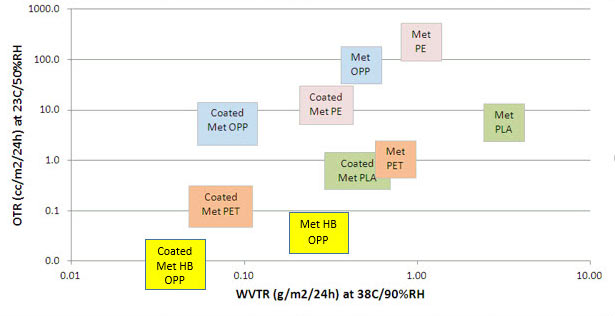

Figure 1 shows the barrier improvement of the top-coating and metallizing process in a single pass for various films compared to simple metallization. Barrier properties are vastly improved for all the films. Coated and metallized polyethylene terephthalate (PET) and oriented polypropylene (OPP) can exhibit barrier properties similar to foil. Similarly, coated and metallized poly lactic acid (PLA) can achieve barrier properties equal or greater than metallized PET, increasing the potential use for this type of film.

Figure 1: Barrier properties for coated and metallized films in one step, compared to traditional metallizing